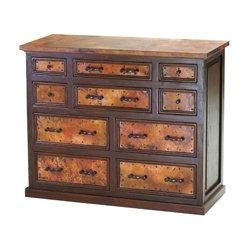

Rustic Copper Furniture

Add warmth, texture, and artisan charm to your home with our Rustic Copper Furniture collection. Each piece is handcrafted using genuine hand-hammered copper, paired with rich reclaimed barn wood and forged wrought iron to create furniture that’s both bold and beautiful.

This collection is all about character—from the subtle variations in the copper’s patina to the weathered grain of 100+ year-old reclaimed wood. Whether you're furnishing a bedroom, living room, or dining space, our rustic copper pieces bring a stunning blend of rugged luxury and earthy sophistication.

Every copper surface is carefully worked by hand, giving it a warm, organic glow and a naturally distressed finish that only improves with age. Paired with sturdy hardwood frames and iron detailing, these pieces aren’t just furniture—they’re functional works of art.